Printable Page

Printable Page

Email This Page

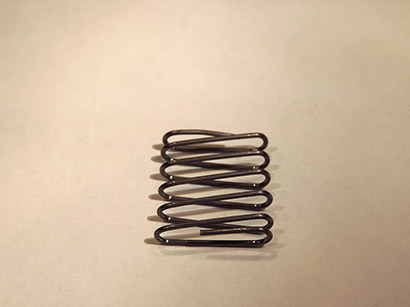

Email This PageForming of a Chrome Silicon Spring for the Automotive Industry

At R.C. Coil Spring Mfg. Co., Inc., we manufacture vast quantities of springs that exhibit an elevated level of quality which is in high demand in the automotive industry. We produced the compression cam spring highlighted here for use in a car starter. Material of construction was .0258" diameter chrome silicon wire, chosen because of its ability to withstand high stresses and repeated impact loading. Manufactured using our high-tech coil compression equipment especially designed to create rectangular forms, this cam spring featured 5 ¼ coils wound to a length of 0.460” with elliptical diameter of 0.4" x .2". Tightly controlled and continually monitored production processes allowed us to repeatedly uphold ± 0.010" tolerances, first part to last, over a high volume production run.

Completely satisfied with the quality of this spring, the client contracted with us to supply 5 million units on an annual basis, which we produce in lots of 250,000 per release within a 4-5 week timeframe.

To learn more about this project, or our ability to supply high volumes of close tolerance springs, contact us today.

Formed Stainless Steel Compression Spring for the Aerospace Industry Project Highlights

- Project Name & Description

- Cam Spring for Car Starters

- Capabilities Applied/Processes

- Forming

- Equipment Used

- Compression Machine for Rectangular Parts

- Equipment Used to Manufacture Part

- Spring Machine

- Overall Part Dimensions

- Length: 0.460"

Diameter: 0.4"/.20" ( Elliptical)

Coils: 5 ¼

- Tightest Tolerances

- ± 0.010"

- Material Used

- .0258 Chrome Silicon

- Industry for Use

- Automotive

- In Process Testing/Inspection Performed

- In-House Visual, Micrometers

- Volume

- 5 Million/250,000 release

- Delivery/Turnaround Time

- 4-5 weeks per release after set up

- Delivery Location

- Laredo, TX

- Standards Met

- Customer Specifications